Want to buy your perfect checks or stripe pattern for tablecloths? Don’t get confused between yarn-dyed and piece-dyed fabric. Let’s start our knowledge exploration by answering What is yarn dyed fabric?

Yarn dyed fabric is the kind of fabric that is made by dyeing the yarns before they are woven or knitted together. A more consistent color and unique pattern can be created in this way.

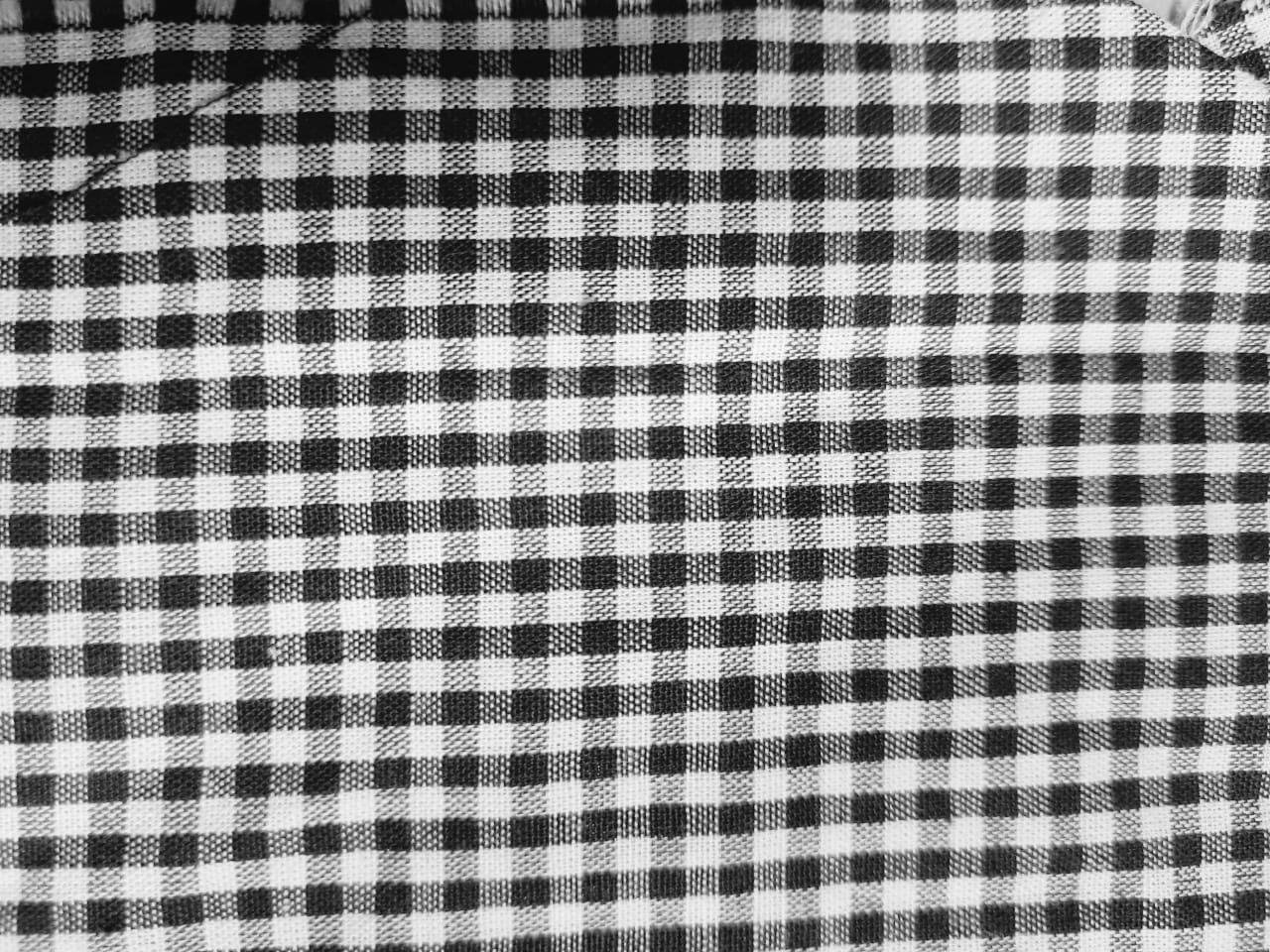

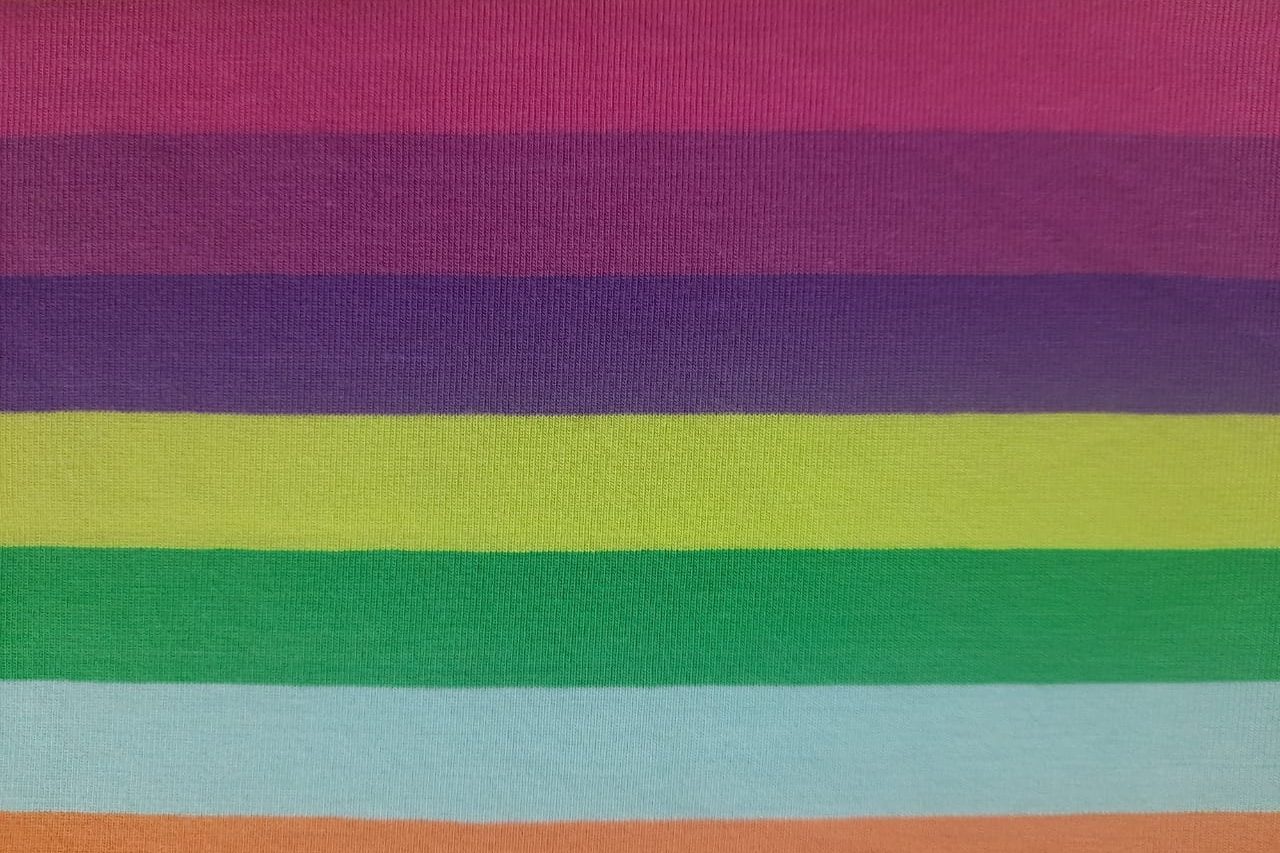

Yarn dyed fabric is often used for shirts, towels, and other garments that are made to be durable and have long-lasting colors. Often it includes gingham checks, chambray linen, dobby patterns, striped cotton

Yarn-dyed fabric is a cloth that uses dyed yarns. The yarns are first dyed and then the fabric is woven or knitted from them. This results in a fabric with a very intricate and beautiful design.

Yarn-dyed fabrics are often used for quilts, tablecloths, and other home decor items.

What is yarn dyed fabric?

When yarn is dyed prior to weaving or knitting, such kind of fabric is called yarn dyed fabric. As yarn is dyed before, good control is possible on creating various patterns on the fabric.

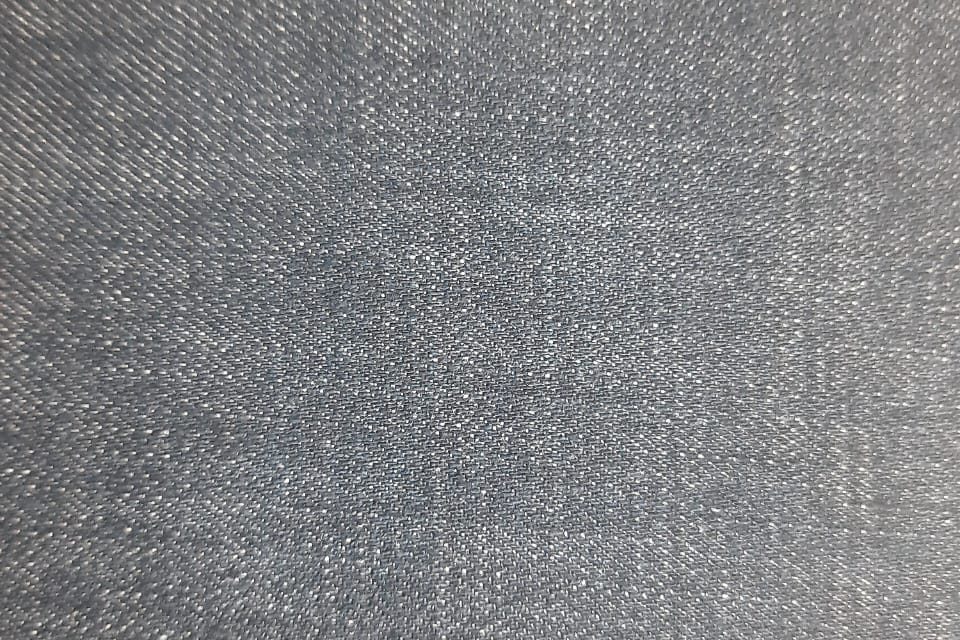

Amazing check patterns, stripe patterns, ikat patterns, plaids can be created. Denim is a common example of yarn dyed fabric. Two sets of yarn: dyed warp yarn and undyed weft yarns are used to make denim.

The yarns are first dyed in large skeins using either a hand-operated machine or an automated system.

They are then wound onto smaller spools called cops and delivered to the weaving or knitting factory.

2 Steps to make Yarn dyed fabric?

Yarns are dyed in package form, hank form, space dyeing or warp beam dyeing. Yarns are given desired color and appearance and that makes the fabric colorful. Several steps including yarn preparation, dyeing and finishing are carried out.

Preparation:

Before dyeing, yarn preparation is a must-going process. All impurities, dirt, oil and wax etc are removed from the yarn surface.

If yarns are going through a sizing process, then they must go through desizing, scouring and bleaching.

If you don’t know why sizing is done, then you need to look into the fabric. Woven fabric has two sets of yarn. One is warp yarn and the other is weft yarn.

Sizing is required to strengthen the warp yarns as they are subjected to a higher tension during weaving. All these processes create a clean base that facilitates the subsequent dyeing process.

Yarns are made of cotton, silk, wool, polyester or nylon fiber. But the preparation process is most important for natural fibers.

Dyeing:

Once the yarns are prepared, they are ready to dye! Package, space, skein or beam dyeing techniques can be used to dye yarns.

- Skein Dyeing: In skein dyeing, yarns are wound into loose coils or hanks and then immersed in dye baths. This method allows for even dye penetration and is commonly used for natural fibers like cotton or wool. The hanks are often mounted on dyeing machines or dyeing cones to facilitate the dyeing process.

- Package Dyeing: Package dyeing involves dyeing yarn wound onto perforated cylindrical packages, such as dye tubes or dye cones. This method is often used for synthetic fibers or yarns with higher tensile strength. The dye solution is circulated through the packages, ensuring uniform dyeing.

- Beam Dyeing: Beam dyeing is primarily used for large-scale production. Yarns are wound onto a perforated beam, and the beam is then submerged in a dye bath. This method is efficient for dyeing a large quantity of yarn at once.

Once the yarn is dyed, they are taken to weaving or knitting sections. In weaving sets of dyed warp and weft yarns are used. Sometimes, dyed warp and un-dyed weft yarns are also used to create variety in the fabric.

In the knitting section, sets of dyed yarn are used to knit tubular fabric. Then the fabric is silted to make knitwear.

9 Differences Between Yarn Dyed Fabric & Piece Dyed Fabric

Yarn Dyed Fabric

Piece Dyed Fabric

You can easily make a difference by observing yarn dyed fabric and piece dyed fabric. Have a look below!

| Topics | Yarn-Dyed Fabric | Piece-Dyed Fabric |

| Definition | The fabric made from dyed yarn that means yarn is dyed before weaving or knitting. | The fabric that is dyed after weaving and knitting. Any woven or knitted fabric that is dyed later is called piece dyed fabric |

| Appearance | Has a distinct pattern or design, as the yarns are dyed in different colors before weaving | The entire fabric is dyed in a solid or single color |

| Variety | Various colors, patterns, checks, stripes, gingham checks, ikats or plaids can be produced as individual yarns are dyed | Limited colors and patterns available |

| Color Fastness | Generally has excellent color fastness, as the dye is incorporated into the yarns during the dyeing process | Color fastness varies on the method of dyeing and type of dye used. Such as, Direct dye has poor wash fastness where as vat dye has poor rubbing fastness. |

| Fabric Structure | Can be woven or knitted with different fabric structures, such as plain, twill, or jacquard weaves | Relies on the structure of the already woven or knitted fabric |

| Durability | Less prone to fading or washing out | Susceptible to fading over time depending on types of dye. |

| Cost | Yarn-dyed fabrics often require more time and resources for dyeing individual yarns, making them relatively more expensive | Piece-dyed fabrics are generally less expensive due to the simplicity of the dyeing process |

| Application | Commonly used for garments, tablecloth, bed sheets and upholstery fabrics | Solid-colored garments, lining fabric, and basic apparel items are produced from piece dyed fabric |

| Examples | Madras fabric, gingham check, Stripes, denim fabric | T-shirts, basic cotton fabrics, jersey knits |

10 Key Differences Between Yarn and Fabric?

| Topics | Yarn | Fabric |

| Definition | Continuous strands of fibers, either natural or synthetic, twisted or spun together | Flexible material made by interlacing yarns, threads, or fibers |

| Composition | Various fibers, for example cotton, wool, silk, polyester, nylon, acrylic etc. are used | Comprises one or more yarns, that may be of different fibers or the same |

| Form | Often comes as long and continuous strands or threads | Commonly found in four forms like woven, knitted, non-woven, or braided |

| Size | Thickness or diameter varies depending on the type of yarn and its intended use | Thickness of fabric depends on the no. of yarns per inch or the density of interlace in woven fabric or stitch length of loops in knitted fabric. |

| Structure | Yarn can be spun in different twill direction like S or Z direction to achieve desired strength and characteristics | Fabric structure depends on the method of interlacing or method of knitting. For example, plain weave, satin weave, twill weave or single jersey or double jersey knit |

| Flexibility | Relatively flexible and can be easily manipulated or shaped | Fabric can have varying degrees of flexibility, ranging from stiff and structured to soft and drapable fabric |

| Function | Used for creating fabrics through weaving, knitting, or other fabric production processes | Clothing, apparel, upholstery, bedding, or industrial textiles are made from fabric |

| Texture | Yarns can have different textures, including smooth, coarse, fuzzy, or textured, depending on the fiber and yarn manufacturing process | Fabric texture is determined by the combination of yarns used and the type of weave or knit pattern |

| Coloring | Dyeing is carried out both before or after fabric production | The color and pattern of the fabric depend on the yarns used, the dyeing or printing methods employed, and the fabric structure |

| Examples | Spun cotton yarn, wool yarn, nylon yarn, Core spun yarn, ring yarn, rotor yarn, wrap yarn, air-jet yarn or polyester filament yarn | Denim, satin, chiffon, fleece, flannel, velvet, twill or jersey fabric |

When to Style Yarn Dyed Fabric?

While you might think that yarn dyed fabric is best suited for winter garments, it can actually be used for clothing all year round! The key to using this type of fabric successfully is to choose the right weight and style of garment for the season.

For example, in the spring and summer, yarn dyed fabric can be used to make lightweight shirts, skirts, and dresses.

Look for fabrics that are made with natural fibers like cotton or linen, which will help keep you cool when the temperatures start to rise.

In the fall and winter, opt for heavier yarns like wool or cashmere to create cozy sweaters, jackets, and scarves. No matter what time of year it is, yarn dyed fabric can add a unique touch to your wardrobe.

Some yarn dyed checks or stripe fabric produces amazing summer wear for any beach or pool party. Whereas some heavy weight fabric may produce thicker clothing that are perfect for your winter wear.

Gsm of your clothing will determine if it can be used in used in cold weather or will be a perfect match for your summer outing.

So don’t be afraid to experiment with this versatile material – you might just find your new favorite piece of clothing!

Can Yarns be Hand Dyed?

Yarns can easily be hand dyed with a little ingredient at home. It’s up to you, which dye would you prefer for your yarns. Cotton yarns can be dyed easily with reactive, direct or vat dyes.

For instance, if you are dyeing your yarns with direct dye, take a bowl of hot water and mix direct dye and salt to it. You can add some vinegar also. That’s all for it.

If reactive dye is used then soda ash is a must have. Again, vat dyes require hydrose and caustic soda for dyeing. But if you are think of polyester yarn dyeing then you need disperse dye and dispersing agent.

Wait! Dyeing yarn with hand is too easy to think. You can use the materials right into your kitchen for natural dyeing. Skin of onion, turmeric, red cabbage, beet root, lavender etc are good alternatives for natural dyeing.

Just take a bowl of hot water, mix vinegar and salt to them and mix the colored water coming from the onion skin. Let a day to set and dry that out.

5 Features Offered by Yarn Dyed Fabric

Denim

Yarn-dyed fabrics offer several advantages over fabrics dyed after weaving or knitting:

- Colorfastness: Yarn dyeing ensures that the color is deeply absorbed by the yarn, resulting in excellent colorfastness. The colors are less likely to fade or bleed, even after multiple washes.

- Durability: Since the yarns are dyed before weaving, the color is evenly distributed throughout the entire yarn. This enhances the fabric’s durability, as the color is less prone to wear or abrasion.

- Versatile Designs: Yarn dyeing allows for intricate and complex patterns to be created, such as plaids, stripes, and checks. These designs can be precisely aligned and repeated, resulting in visually appealing fabrics.

- Reversible Fabrics: Yarn-dyed fabrics often have the same appearance on both sides, making them reversible. This feature is particularly desirable for clothing items like shirts or dresses where both sides of the fabric are visible.

- Texture and Feel: Yarn dyeing preserves the natural texture and feel of the yarn, as the dyeing process occurs before the fabric is formed. This can result in a more tactile and luxurious fabric compared to those dyed after weaving or knitting.

How to Identify Yarn Dyed Fabric?

Single Jersey Fabric (Yarn Dyed)

Identifying yarn-dyed fabric can be done by examining the fabric closely and looking for specific characteristics. Here are some ways to identify yarn-dyed fabric:

Check the Front and Back: Yarn-dyed fabric often exhibits the same or very similar color on both the front and back sides. This is because the yarns used in the fabric are dyed before weaving or knitting, ensuring that the color penetrates throughout the yarns

Examine the Edges: Look at the cut edges of the fabric, such as the raw or selvedge edges. In yarn-dyed fabric, the color will be consistent from the face to the edges, indicating that the yarns themselves were dyed.

Inspect the Reverse Side: Flip the fabric over and observe the reverse side. In yarn-dyed fabric, you will see the same pattern or design as the front side, but in a reversed orientation. This is because the yarns were dyed before weaving or knitting, creating a consistent pattern throughout the fabric.

Consult Fabric Information: Check the fabric label or consult the manufacturer’s information. Yarn-dyed fabrics are sometimes explicitly mentioned or labeled as such. However, it’s worth noting that not all fabric labels may specify the dyeing method.

By combining these visual observations and considering the characteristics of the fabric, you can make an informed judgment about whether a fabric is yarn-dyed or not. It’s important to note that some fabrics may have a combination of yarn-dyed and piece-dyed sections, especially in complex designs or fabrics with multiple colors.

End Uses of Yarn Dyed Fabric

Yarn-dyed fabric is used for various purposes:

- Tablecloth

- Apparel

- Gingham checks

- Ikats

- Plaids

- Shirts

- Pants

- Bed sheets

Is Yarn Dyed Fabric Good for Your Project?

When it comes to deciding what kind of fabric to use for a project, there are a lot of factors to consider. One important factor is whether you want the fabric to be yarn dyed or not. Yarn dyed fabric is made by dyeing the individual yarns before they are woven together.

This results in a very uniform and consistent color throughout the fabric. Non-yarn dyed fabrics can have more variation in their color because the dye stuffs are applied after the fabric has been woven. So, is yarn dyed fabric good?

There are definitely pros and cons to using yarn dyed fabric. One advantage is that you can achieve very rich and saturated colors with yarn dyed fabrics.

The downside is that they can be more expensive than other types of fabrics, and the colors may fade over time if they are not treated properly.

Overall, it really depends on your personal preferences and what you plan to use the fabric for as to whether or not yarn dyed fabric is right for you.

Which Fabric is Commonly Yarn Dyed?

Yarn dyeing is a process of coloring yarns before they are used to weave or knit fabrics. The yarns are first wound onto cones or bobbins and then soaked in dye baths. The dye penetrates the fibers, giving them an overall color.

Yarn dyeing is different from piece dyeing or fabric printing because the colors are more evenly dispersed and there is no design or pattern on the fabric.

Common fabrics that are yarn-dyed include linen, denim, chambray, gingham and madras. Linen is usually yarn dyed in one solid color, while denim and chambray can be yarn dyed in multiple colors to create a marbled effect.

Gingham and madras are often printed rather than yarn dyed, but some manufacturers do offer yarn-dyed options.

Wrapping Up on What is yarn dyed fabric?

Yarn dyed fabric Is an amazing and versatile fabric. They are perfect for any project no matter it’s summer or winter! Their various intricate patterns create a gorgeous outlook.

Salma Hasin the author of this site completed her BSc. in Textile Engineering (Wet Processing Engineering). She wants to share her knowledge to help students in their studies and businessman & entrepreneurs in their businesses in making wise decisions fast.