Solvent scouring appears to be an alternative to aqueous scouring and particularly suitable for polyester and woolen goods. This process not only permits scouring but also simultaneous scouring and de-sizing or even partial bleaching in one step. Solvent scouring is also useful for the removal of lubricating oils from knitted polyester, oligomer from polyester and bulking of knitted goods.

Solvent scouring is the treatment of fabrics in a solvent medium to remove all the impurities, dirt, oils from the fabrics.

Let’s find more about solvent scouring below

Suitable solvents for solvent scouring

The most suitable solvents for textile processing are-

- It is seen that waxes are effectively removed by benzene, chloroform or carbon tetra-chloride. But now they are not used because of-

- Toxicity

- Fire hazard

- High

- The following chlorinated organic solvents are used widely because of their-

- Chemical inertness

- Stability to recovery

- Good wetting ability

- Non-corrosivenes

- The chlorinated hydrocarbons-

- Tetrachloroethylene (perchloroethylene)

- Trichloroethylene

- 1,1,1- trichloroethane

- Perchloroethylene is widely used in drum machine

Solvent Properties

Boiling Point: Suitable temperature at which solvent can be converted from liquid to a gas.

Specific Heat: Specific heat is the amount of energy needed to raise one gram of solvent to one degree centigrade.

Latent Heat of Evaporation: The amount of energy needed to vaporize one gram of solvent (Calories/gram).

Factors to be considered while choosing solvents

Solvents intended for use in textile processing should ideally be-

- Inexpensive

- Readily obtainable

- Non-toxic

- Non-flammable

- Stable to repeated recovery

- Inert to textiles

- Non-corrosive.

Important Factors for Solvent Scouring

- Stability of solvents to recovery by distillation or by adsorption process.

- The recovery of stabilizer in the solvents.

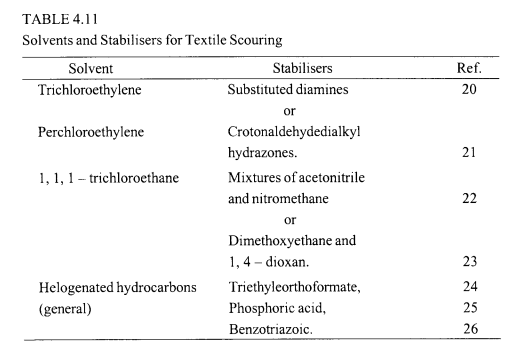

- The stabilizers recommended for different solvents are shown in the following table:

Image Source: Basic Principle of Textile Coloration

In certain processes ‘booster solvents’ are added to perchloroethylene. Soil removal in chlorinated hydrocarbons can be improved by the addition of solvent detergents, such as mono-ethanolamine, alkyl-benzene sulphonate, alkyl poly (glycol ether) and alkyl pyridine chloride. Chlorinated hydrocarbons containing are capable of dissolving in water and hence enhances detergency.

Solvent scouring process

The commercial process where fabrics are cleaned with organic solvents is said to be “Dry Cleaned”. This process is not used widely. But when a single residue of impurities can cause downstream problems that means for the crucial results, this process is carried out.

For the fabrics where de-sizing is not carried out, solvent scouring is a good solution. It can remove all dirt, knitting oils, sizing coating effectively. This process is proved extremely suitable for the knitted fabrics from polyester, nylon, wool. Wool grease is removed very efficiently.

Continuous solvent scouring machinery

Company Unit

Bohler and Weber C 1600 / C 1800

ICI Markal

Bruckner Solvanit

Dow Dow Scouring System

Rimmer Vibro Scour

Riggs and Lomband Scour-kleen

Neil & Spencer Libatex

Process description

Basically, solvent scouring is a refinement of dry-cleaning and is carried out either batch-wise or continuously.

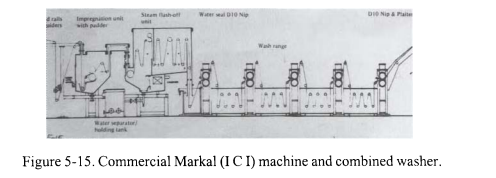

Image Source: Basic Principle of Textile Coloration

- In the above figure, ICI’ s Markal process, the dry cloth first passes through trichloroethylene (TCE) in the de-waxing vessel which is divided into number of separate compartments.

- From the last compartment the cloth passes through a solvent seal and then a heavy mangle, where much ex-trained solvent is removed from the cloth.

- The cloth then passes through a chamber into which steam is injected.

- Thus rapid evaporation of solvent in the cloth is occurred.

- At the same time, the mixture of steam and TCE vapor is condensed and returned to the solvent seal where the solvent and water are separated.

- In alternative method, the solvent is removed from the cloth by the use of an enclosed hot water (95°C) bath instead of steam chamber.

- After passing through the water wash tank, the cloth leaves the scouring machine saturated with water.

Image Source: Basic Principle of Textile Coloration

Advantages of Solvent Scouring

- Reduced water pollution

- Reduced energy cost and consumption

- Effective removal of impurities

- Solvent preparation gives excellent results in terms of-

- Uniformity

- Reproducibility

- High absorbency

Difficulties of solvent scouring

- The need for systems to recover the solvent from fabrics after processing.

- Solvent can remove binders from bowl fillings.

- Solvent may remove adhesives from laminated bowl covers.

- Can rapidly attack the conventional rubber coverings with expensive effect.

- At high temperatures solvent absorption into the fiber web increases but decreases with the action in subsequent steaming operation that can lead to embarrassing side effects.

Wrapping Up on Solvent Scouring

Solvent scouring is a good alternative to conventional scouring that uses lots of chemical in aqueous medium. It effectively eliminates all the dirt and residue from the stuffs. The most important fact is solvent scouring is eco-friendly so it won’t add loads to the environment.

If you are interested to know about scouring, then have a look: What is scouring? Get a comprehensive look!

Salma Hasin the author of this site completed her BSc. in Textile Engineering (Wet Processing Engineering). She wants to share her knowledge to help students in their studies and businessman & entrepreneurs in their businesses in making wise decisions fast.